- Description

- Specifications

- Certifications

- Document Center

- Handing Chart

Description

Pemko CFM83HD1HT Continuous Geared Hinge Full-Mortise Heavy Duty Hospital Tip Clear Anodized Finish - 83" Fire Rated - UL10C - Positive Pressure

The Pemko CFM83HD1-HT Continuous Geared Hinge Full-Mortise Heavy Duty Hospital Tip Clear Anodized Finish Fire Rated - UL10C - Positive Pressure, Pemko's CFM83HD-1-HT Hospital Tip heavy-duty anodized aluminum Full Mortise units are designed mainly for new door applications

Features:

- Fasteners are No. 12-24 x 7/16" FHUC, Type C, thread forming, no tapping required

- Applied to conceal both leaves

- With a continuous hinge, typical alignment problems (such as door sag and binding) are eliminated.

- The continuous hinge distributes load stress uniformly along the full length of the door and frame.

- The gear design of the continuous hinge ensures the symmetrical operation of each leaf.

- 1/2 lb. or less operating force is required to operate most doors, regardless of size.

- The low operating force feature makes continuous hinges ideal for doors used by the physically challenged.

- The continuous hinge acts as reinforcement for both the door and frame.

- A high degree of security can be achieved for exterior openings or restricted spaces by using a continuous hinge. With the geared construction and the full-length channel cap, the common gap between the door and frame is sealed, which provides security against prying.

- In addition, the closing of this gap protects against pinching fingers indoors in public areas, particularly those where children are present.

- Sight-proof design of the continuous hinge provides privacy for lavatories, executive offices, or file rooms.

- PemkoHinge has increased critical stress points of the leaf extrusions, which provides additional strength and rigidity to the completed product.

- PemkoHinge has a new bearing design that eliminates premature wear, guarantees proper alignment, and requires fewer bearings to carry more weight. This new bearing is produced for Pemko using a chemical composition and injection process that provides a stronger, more accurately formed bearing.

- PemkoHinge is designed with inter-meshing gear segments in the hinge which provide 50% more bearing surface. With a more bearing surface, less wear results.

- PemkoHinge also goes through the anodizing process after completing all machining. This means the machined aluminum surfaces that are in direct contact with the bearing have a smoother, harder surface, thereby reducing wear.

- PemkoHinge maintains uniform bearing spacing the full length of the hinge even when lengths exceed 10 ft.

- PemkoHinge uses #12-24 size fasteners instead of #10. (#12 Tek fasteners available upon request).

- PemkoHinge commercial models are ideal for use on lead-lined doors (i.e. hospital X-ray rooms), without requiring special screw locations.

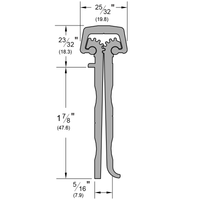

Specifications

| Finish: | C - Clear Anodized |

| Length: | 83" |

| Width: | 25/32" (19.8 mm) |

| Height: | 2-9/16" (65.1 mm) |

| Manufacturer: | Pemko |

Certifications

| BHMA: | BHMA Certified |

| UL: | Fire Rated - UL10C - Positive Pressure |

| Other Certifications: | PemkoHinge Fire Rating - UL76Y2 |

Document Center

Handing Chart